-

Paper Product-Making Machine

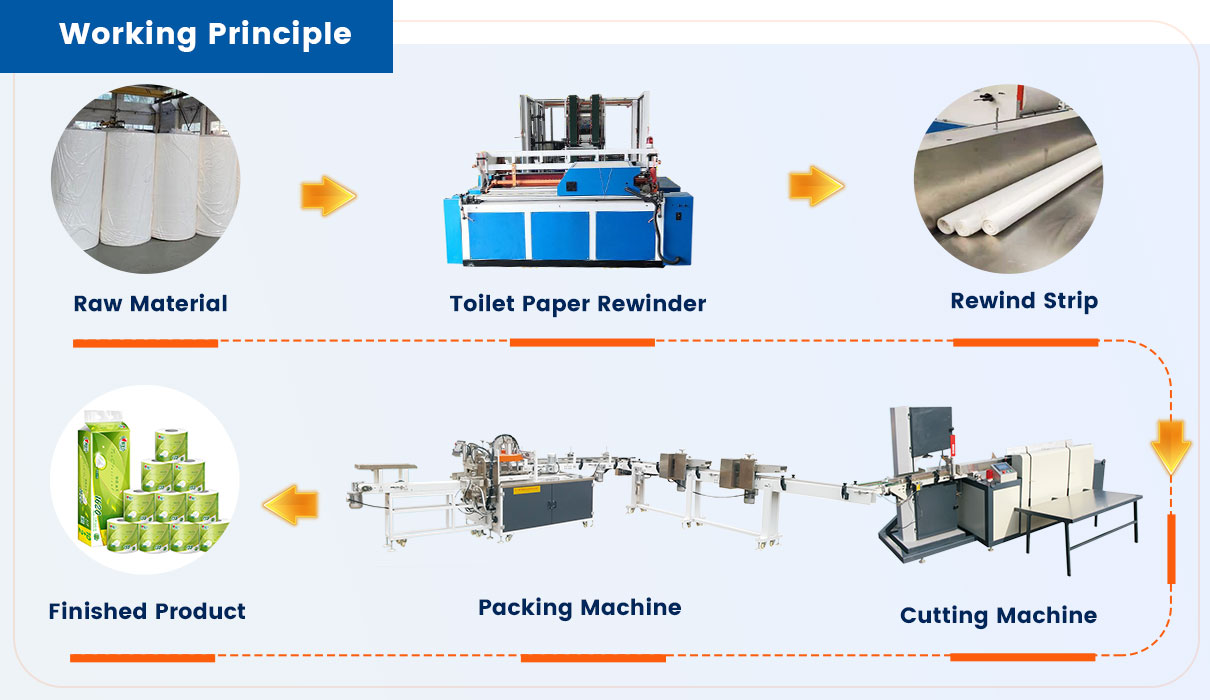

The toilet paper production line consists of a toilet paper rewinding machine, cutting machine, packaging machine. The tissue Jumbo Rolls is rewound into long strips by the rewinder, then cut into small rolls by the band saw paper cutter, and finally bagged and sealed. This production line can be used to produce toilet paper rolls with 2-5 layers.

Put the parent roll on the paper feed frame, and pass the parent roll into the paper feed roller through the automatic paper loading and paper feeding device of the paper feed frame. There is a tension bar device in front of the paper feeding roller to flatten the paper surface, and then enters the punching device to punch holes, and then enters the roll guiding device. The rolling paper is completed through repeated guide rolls by guide rolls and pressure rolls. After reaching a certain specification, the machine will stop winding and automatically push out the roll paper. At the same time, the paper cutter cuts the roll paper and automatically sprays glue to seal it to complete the rewinding.

According to the different needs of different customers, such as the customer's budget, site size, requirements for equipment automation, etc., YG Machinery can provide customers with the following two toilet paper production lines. In addition, the production line can also be customized according to the needs of customers.

low investment cost

Capacity: 2t/8h

3-4 people to operate

For small toilet paper manufacturers

PLC control system

Automatic rewinding, cutting, packaging

High productivity and security

Capacity: 2-4t/8h

Automatic Band Saw Paper Cutter

Automatiac Multi-roll packing machine

Automatiac Single roll packing machine

Email Us: packing@yugongmachine.com

Email Us: packing@yugongmachine.com  Whatsapp: +86 13838270129

Whatsapp: +86 13838270129 Address: 26/27F, Block B, Jingsha Plaza,

No.8 Jingguang South Road,Erqi District, Zhengzhou, Henan, China

Address: 26/27F, Block B, Jingsha Plaza,

No.8 Jingguang South Road,Erqi District, Zhengzhou, Henan, China Business office: 26 / 27F, block B, Jingsha Plaza, No. 8 Jingguang South Road, Erqi District, Zhengzhou, Henan, China

Business office: 26 / 27F, block B, Jingsha Plaza, No. 8 Jingguang South Road, Erqi District, Zhengzhou, Henan, China